Custom Manufacturing Software Development Services

Boost the efficiency of your manufacturing operations and supply chain with GeekyAnts.

From streamlining procurement to inventory and order management, we provide software development solutions for the manufacturing industry that help you achieve peak process efficiency.

CASE STUDY

END-TO-END MANUFACTURING SOFTWARE AND APP DEVELOPMENT SERVICES

We Build Innovative Workflows and Software for Industry 4.0 to Streamline Operations

Our software and app development services for the manufacturing industry is from a foundation of deep industry knowledge and experience. We provide a dedicated team for your project delivery. They take care of the requirements end-to-end or function as an extended team. This ensures we deliver solutions that are aligned with your business goals and ROI targets.

Digital Transformation & Workflow Automation

- AI Workflows and Automation

- Process Automation

- Process Control Applications

Supply Chain Management

- Supplier Collaboration Portals

- Inventory Tracking and Just-In-Time Delivery

- Logistics and Warehouse Management Software

Manufacturing Operations Applications

- ERP and MES Systems

- Digital Twins for Process Simulation

- Performance Monitoring & Analytics Dashboards

AI-POWERED EXPERTISE

Maximize ROI from AI-Adoption with Our Manufacturing Industry Focussed AI-Engineering

Integration and IoT Devices and Sensors:

Data Filtration and Segmentation

Historical Data Analysis

Performance Benchmarking

Predictive Analytics and Forecasting

Energy Consumption Tracking

Incident and Anomaly

Role-based Access Control

SUSTAINABILITY EXPERTISE

Drag and Drop Dashboard for Sustainability-focussed Manufacturing

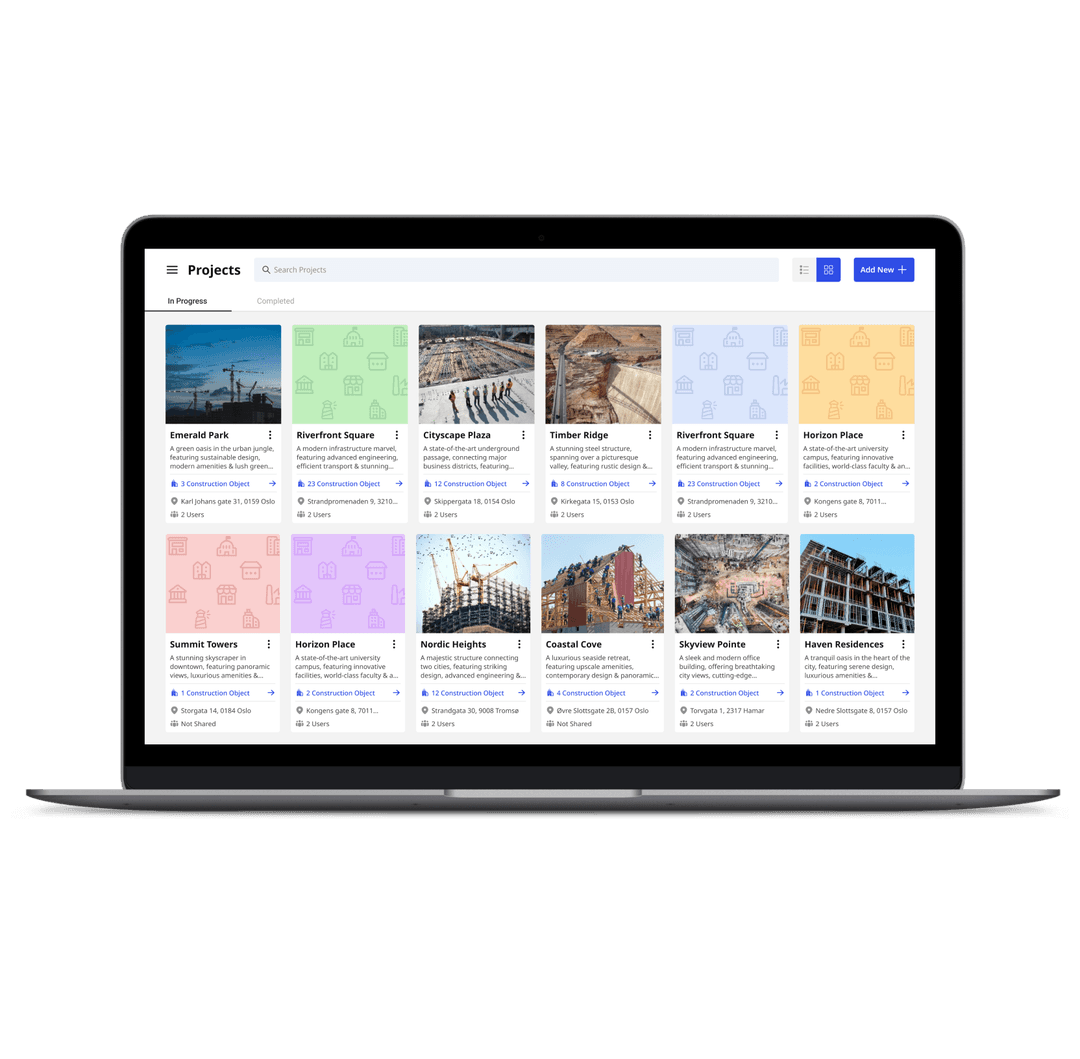

We improved an existing web application into a platform that holds the potential to revolutionize construction project management. Key deliveries were a revamped UI, improved maintainability, better integration with third-party utilities.

The final product was a comprehensive suite to streamline construction management. It was packed with features like project management, construction object and version tracking, inventory control, and GWP calculations.

Users Onboarded

Major Features Built

Date-points Supported

CUSTOMIZED MANUFACTURING SOFTWARE AND APP SOLUTIONS

How We Deliver Custom Manufacturing Software Development Services for Industry 4.0 and the Age of AI

We follow a standardized process that brings in agility and innovation to the partnership. At the same time, we also leave ample room for course correction and adoption of innovative manufacturing software and app development solutions. Each step of the partnership is designed to soak in feedback and create the best version of your idea.

Step 01

Idea Generation

Step 02

Discovery Sessions

Step 03

Market Research

Step 04

MVP Scoping

Step 05

MoSCoW Analysis

Step 06

T-shirt Sizing

Step 07

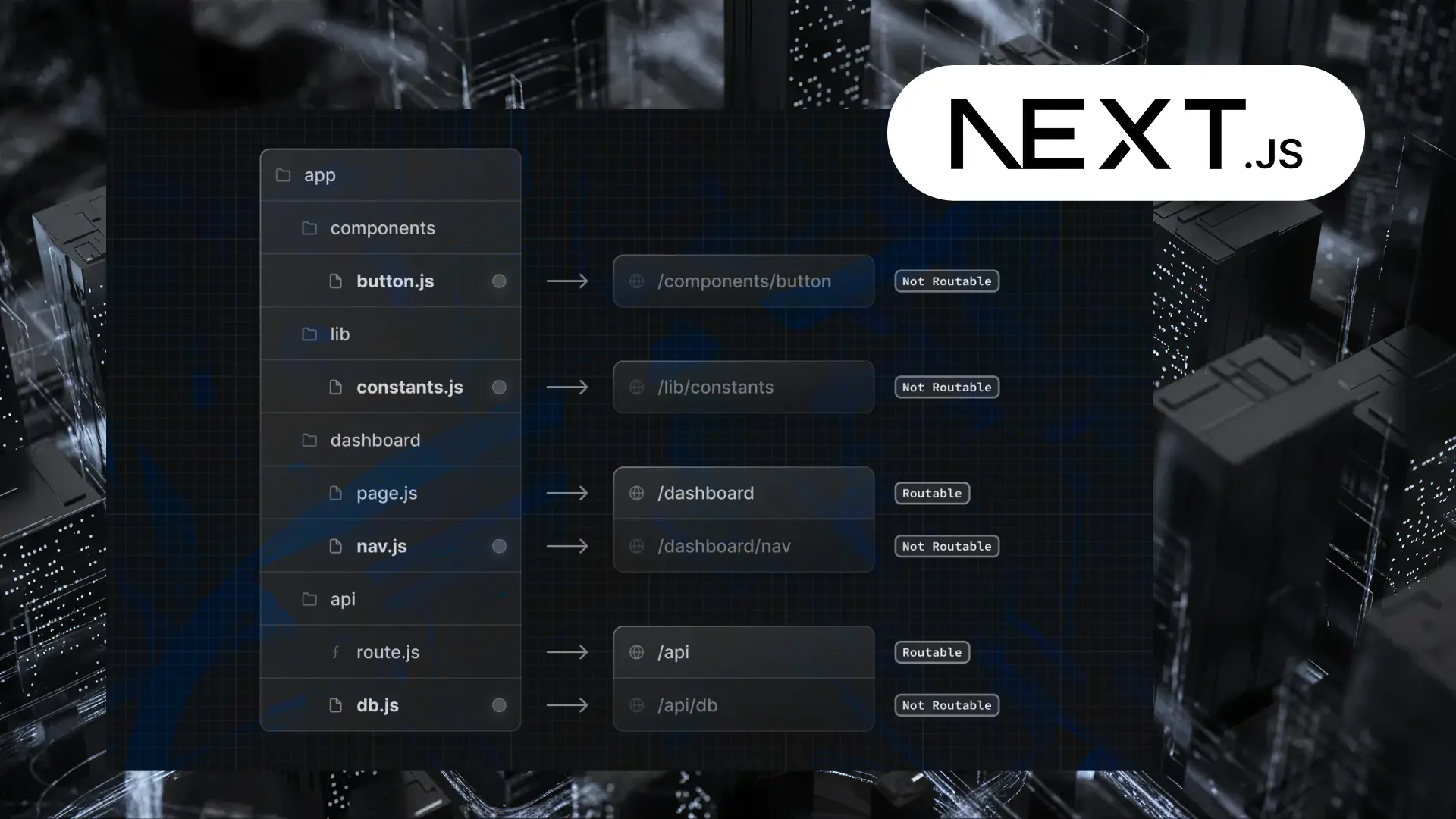

App Architecture

Step 08

Development of the MVP

Step 09

MVP Testing & Review

Step 010

Feedback & Upgrade

PRODUCT SHOWCASE

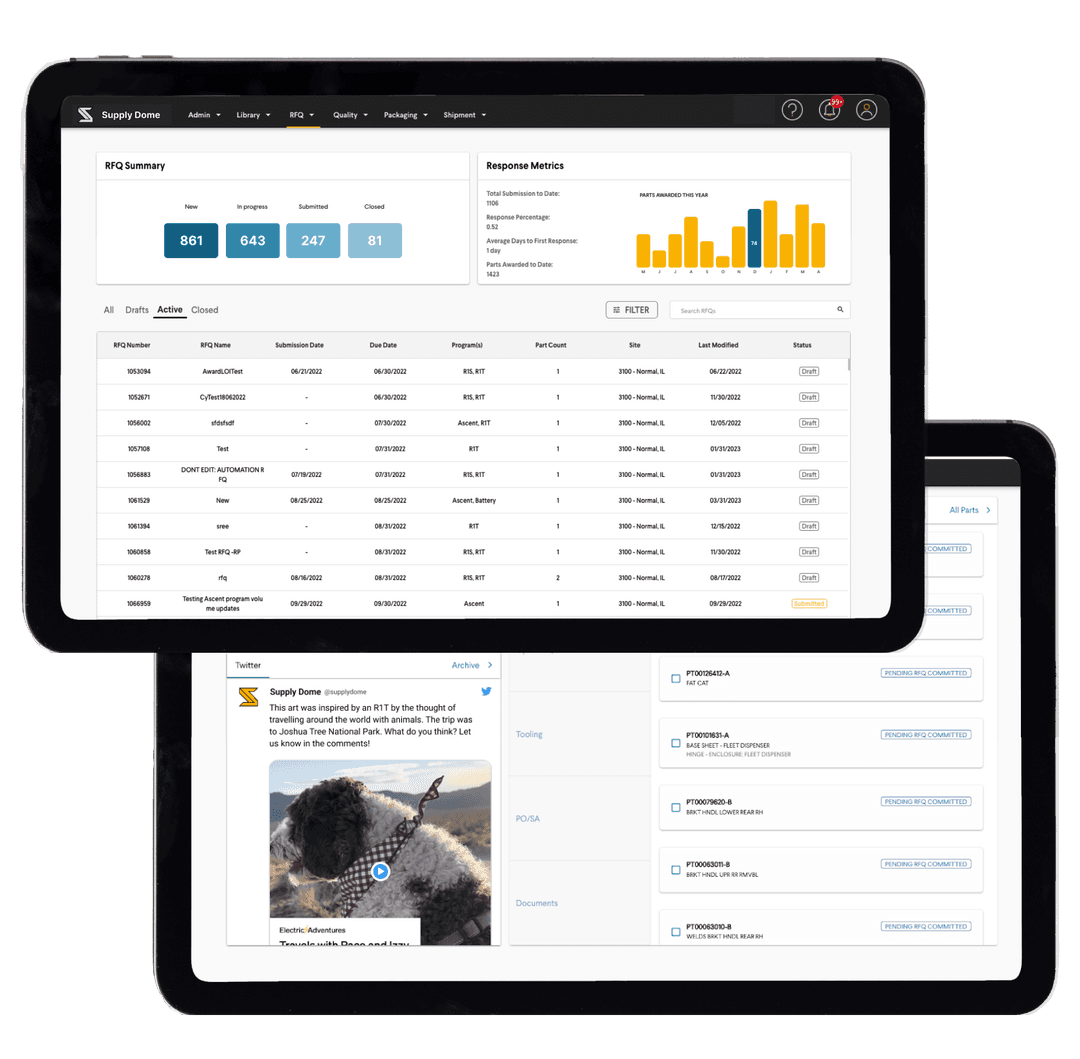

SupplyFlex: Supply Chain Management App that Streamlines Process from Procurement to Delivery

We built SupplyFlex to showcase our app development expertise in manufacturing innovation. It is now a customizable solution that can serve as a good foundation to build strong manufacturing workflows. Features include supplier onboarding, inbound logistics, inventory/warehousing, advanced shipping notices, invoicing, and logistics.

TECHNOLOGY EXPERTISE

We Specialize in AI Solutions, Experience Design, and End-to-End Development Frameworks

GPT

Llama Index

Prompt Engineering

MANUFACTURING INDUSTRY PORTFOLIO

Why Choose GeekyAnts As Your Manufacturing App Development Company

We are a global manufacturing software development company. From creating new softwares to perfecting existing processes, we specialize in end-to-end software and app development services. Our manufacturing software development services ensure the optimum utilization of resources to deliver the best products to end users. Our end-to-end solutions are also use-case specific and based on thorough market research.

Expert Manufacturing Engineers

Manufacturing Projects Delivered

Years of Industry Experience

AI-powered Digital Solutions

We combine our digital expertise with the power of artificial intelligence (AI) to provide solutions like predictive maintenance and anomaly detection.

Enterprise-level Expertise

We excel in creating manufacturing app development solutions that cater to the complexities and demands of the large scale and medium scale manufacturing industry.

Expertise in Smart Dashboards

Effectively monitor and track KPIs, make data-driven decisions, and drive continuous growth with our enterprise-level dashboards tailored to manufacturing companies.

Timely Delivery

Our commitment to delivery timelines is watertight. We follow a strict process to ensure that we deliver apps and other add-ons within the agreed-upon timelines.

Customized Automations

We analyze existing processes and identify the scope for automation and digitization. We use AI, machine learning, IoT, and robotic process automation (RPA).

Scalable Architecture

We build apps to scale. Tech stacks chosen are on how they will scale with changing industry, operations and customer requirements.

Hire Our Manufacturing App Development Experts.

Get a free discovery session and consulting to start your project today.

FAQs

Learn More About Manufacturing Software and Apps Development Services

The cost varies based on complexity, features, customization, and integration needs. At GeekyAnts, we create solutions to match your budget and needs. For example, we built SupplyFlex, a customizable supply chain tool, within budget by using reusable modules. This method saved time and money while meeting the client's needs.

Here’s an estimate of manufacturing software development costs based on application complexity.

App development costs vary depending on the complexity and requirements of the project. Simple app development typically ranges from $8,000 to $16,000 and includes solutions like basic inventory tracking, simple reporting, or standalone task management software. For more advanced needs, average app development costs fall between $16,000 and $25,000, covering tools such as supply chain management systems, IoT integrations, or mid-level ERP solutions. Complex app development, requiring extensive features or integrations, starts at $25,000 and includes applications like AI-driven predictive maintenance systems, multi-module platforms, or large-scale integrations.

These are rough estimates; actual prices depend on the project size, technology, and team skills. For a precise quote, we need to review your specific needs. At GeekyAnts, we offer clear quotes based on your required features and functions.

Development time varies depending on the project's size and complexity. On average, manufacturing software takes 3-9 months to develop. For example, we spent 50,000+ hours on a complex supply chain platform for an E-vehicle manufacturer. This platform, which supports over 215,000 units, was delivered on time. A structured process and regular checkpoints ensured progress. We keep you updated, ensuring timely delivery without compromising quality.

At GeekyAnts, we ensure your software is always running smoothly with 24/7 monitoring and ongoing support. We handle regular updates and performance optimizations to keep your system efficient. Additionally, we conduct quarterly system audits to identify areas for improvement and ensure scalability as your business grows. Whether it's fixing issues, improving performance, or adapting to new technologies, we work closely with you to ensure your software stays aligned with your needs, minimizing downtime and maximizing reliability.

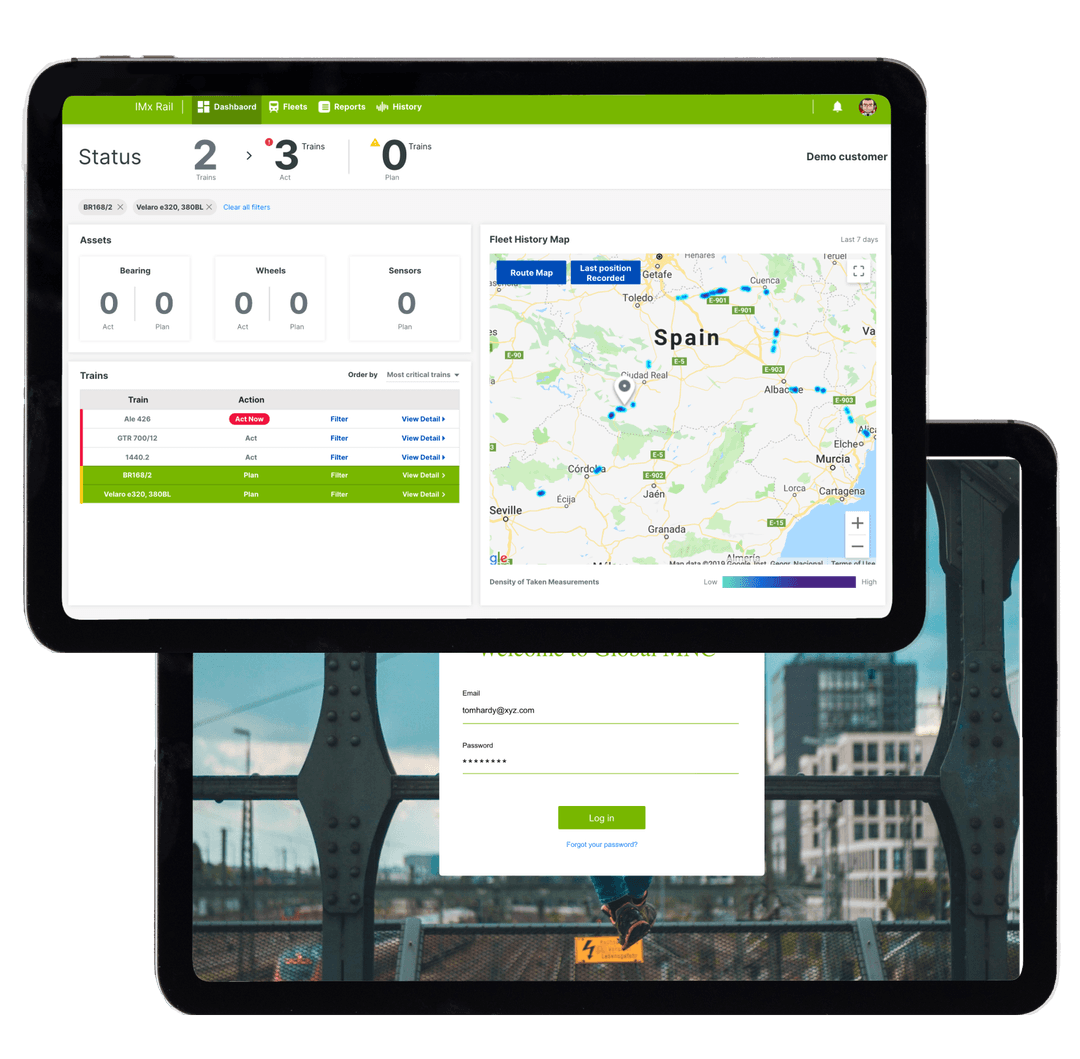

Yes, our solutions are fully customizable and can be tailored to your manufacturing process. For example, For instance, we created a solution for a global MNC, capturing data from 10,000+ sensors across 12 countries, which helped reduce maintenance costs by 30%. Our solutions are fitted to your specific needs, by incorporating features such as real time monitoring and predictive maintenance. We will work with you, whether your line of business is an IoT inspired solution, a specific inventory management system, to ensure that at the end of the day the final product caters to your exacting specifications.

We at GeekyAnts know how crucial it is that your new software integrates easily with your current systems. To ensure seamless integration, we begin with a comprehensive system assessment to thoroughly comprehend your configuration. To make sure your new software will connect and work properly with your legacy systems, we then employ the appropriate methods, such as APIs and IoT connectivity.so your operations continue running smoothly.

For instance, we just added five external data sources to a client's platform that focusses on sustainability. Despite the intricacy, the update was completed without interfering with their regular business activities, demonstrating our ability to manage complex integrations.

Over the years, we've successfully delivered more than 40 projects, with a strong focus on AI-powered solutions, predictive maintenance, and supply chain optimization.

For example, we developed a predictive maintenance system that helped one of our clients reduce downtime by 25%. We’ve also built smart dashboards for over 675 users, providing real-time insights into key performance indicators (KPIs) to help them make informed decisions on the spot.

Our deep understanding of the challenges and needs of the manufacturing sector allows us to design software that not only improves efficiency but also fosters innovation and enhances productivity. Whether it's streamlining operations or driving smarter decision-making, our solutions are built to make a real impact.

At GeekyAnts, we focus on building scalable systems from the ground up. We use flexible architectures like microservices and cloud infrastructure that allow your system to grow alongside your business. We also incorporate predictive analytics for better resource planning and operational forecasting. For instance, we developed an AI-driven platform for an E-vehicle manufacturer that supported over 215,000 units and scaled smoothly as production volumes increased. By leveraging cloud-based solutions and continuously benchmarking performance, we ensure that your system can handle increased demands without compromising on speed or reliability.

At GeekyAnts, data security is a top priority when developing manufacturing applications. We adhere to industry-standard security practices, such as ISO 27001 for information security management and NIST (National Institute of Standards and Technology) cybersecurity frameworks, to ensure comprehensive protection for your systems. Our applications are designed with end-to-end encryption, safeguarding sensitive data during transmission and storage. Additionally, we implement role-based access control (RBAC), ensuring that only authorized personnel have access to specific data within the system. This minimizes the risk of unauthorized access or data breaches. Our systems are also compliant with GDPR and CCPA to ensure that personal data is handled securely and in accordance with legal regulations.

Furthermore, we integrate advanced security mechanisms such as multi-factor authentication (MFA) and OAuth 2.0 for secure user authentication and authorization. Regular security audits, vulnerability assessments, and penetration testing are conducted to identify and mitigate potential risks. We also implement secure APIs with technologies like JWT (JSON Web Tokens) to protect data exchanges between different systems. For backend security, we rely on database encryption, firewall protections, and intrusion detection systems (IDS) to safeguard critical manufacturing data. Our approach ensures a multi-layered defense strategy, protecting your app from threats while maintaining compliance with industry regulations and best practices.

Yes, our solutions are designed to meet the stringent requirements of manufacturing environments, including adherence to standards like CMMC (Cybersecurity Maturity Model Certification) for defense manufacturing contractors and ITAR (International Traffic in Arms Regulations) for manufacturers dealing with controlled goods. By staying compliant with these standards, we ensure that your manufacturing operations run securely, efficiently, and in line with global regulatory expectations.