Table of Contents

How to Build AI-Driven Inventory Management Software for E-commerce

Author

Subject Matter Expert

Date

Book a call

How to Build an AI-Integrated Inventory Management Software for E-commerce Businesses

Key Takeaways

- AI boosts demand forecasting accuracy, optimizes stock levels, and powers real-time tracking to reduce waste and improve delivery speed.

- Custom solutions scale with your business and offer precision, while off-the-shelf tools provide faster setup but limit flexibility over time.

- The process moves from clear objectives to design, development, deployment, and ongoing AI model optimization for maximum impact.

- The best stacks combine modern frontend, backend, AI/ML, cloud, and APIs. MVPs start at $30K–$50K; enterprise builds with advanced AI features can exceed $200K.

The shelf speaks before the data does. One day, it is empty. Next, it overflows. Both cut into margins and trust. In e-commerce, where inventory shifts by the hour, outdated systems miss the signal.

In the US, where speed meets expectation, there is no room for delay. Milliseconds decide who wins the cart. Traditional systems, bound by static rules and batch logic, fall behind. They create blind spots where accuracy slips and action stalls.

This is why businesses now move toward AI-first, cloud-native platforms—systems that scale with precision, not complexity.

The numbers confirm it. By 2025, AI will run most North American warehouses. Nearly half of logistics and retail operations already use AI across their supply chains. Demand curves change overnight. Market signals vanish in minutes. Only real-time, self-learning systems can match that pace.

E-commerce leaders act first. They know stockouts cost trust. Overstock freezes growth. Every late reorder and manual step chips away at momentum. Growth demands real-time visibility, predictive insight, and systems that move as fast as the market does. Cloud-native builds the foundation. AI delivers the foresight. Together, they power inventory systems built for the next move.

Impact of AI in Inventory Management Systems:

AI is transforming inventory from a reactive burden into a predictive engine. Instead of relying on static rules, modern systems learn from trends, seasonality, and shopper behavior. Forecasts adapt. Stock levels sync in real time. Reorders happen automatically. Warehouses run faster, with fewer errors and more strategy, not supervision.

The results speak volumes.

Zara (Inditex Group) slashed global logistics turnaround to just 48 hours using AI-powered stock visibility and predictive demand. Meanwhile, AI-driven systems deliver 95–99% stock accuracy, far outperforming the 63% baseline of legacy tools (IBM, McKinsey).

Fewer stockouts. Lower holding costs. Faster fulfillment. Smarter decisions. From anomaly detection to autonomous reordering, AI empowers retailers to scale with speed, accuracy, and control. This guide breaks down how to build a system that does it all—from architecture to ROI.

What is an AI Inventory Management Application? And Types in E-commerce

Inventory defines outcomes before checkout begins. In e-commerce, where demand shifts fast and margins stay thin, reactive inventory systems slow growth. AI changes that. It studies patterns, predicts demand, and adjusts stock in real time, bringing speed, control, and accuracy across the entire supply chain.

What is an AI Inventory Management Application?

An AI inventory management application is a decision engine. It predicts what sells, when, and where. It automates replenishment, flags anomalies, tracks products in motion, and adapts as market signals shift. Built on real-time data, it runs with speed, learns from change, and scales with business needs.

AI integrates with every operational layer. From forecasting and procurement to warehousing and fulfillment, each function aligns through intelligent automation. It reduces waste. It accelerates fulfillment. It brings clarity across the supply chain.

Types of AI Inventory Management Applications in E-commerce

AI solutions in inventory fall into distinct functional types—each solving a different business need:

- Stock Optimization Systems

Focused on balancing inventory across channels and locations. They minimize holding costs while protecting against stockouts. - Demand Forecasting Engines

Built to analyze trends and align inventory with expected sales. They enable proactive procurement and leaner operations. - Multi-Channel Inventory Managers

Synchronize stock across platforms—own store, marketplace, social commerce, and retail. Accuracy holds across all touchpoints. - Warehouse Intelligence Platforms

Handle layout optimization, picking efficiency, and real-time movement tracking. They reduce friction and accelerate fulfillment. - Supplier & Order Management Tools

Track vendor performance, optimize reorder cycles, and automate communication. These tools ensure reliability and reduce supply chain risk. - Full-Suite Autonomous Systems

Integrate all inventory functions—from sourcing to shelf—under one intelligent workflow. These systems operate with minimal human intervention and maximum scalability.

AI is the core architecture for inventory systems that lead. Businesses that build around this intelligence gain what others chase—accuracy, speed, and control.

Why is Inventory Management Crucial in eCommerce?

Inventory is where profit is made—or lost. When stockouts happen, trust breaks. When excess piles up, cash gets stuck. In e-commerce, where speed defines experience and accuracy defines loyalty, inventory control is everything.

Today’s shoppers expect instant availability. A missing item leads to cancellations, refunds, and churn. Overselling damages credibility. On-time delivery starts with precise stock visibility.

Smart inventory management cuts holding costs, prevents waste, and frees up working capital. Businesses lose up to 11% annually from poor inventory practices; efficiency protects the bottom line.

AI brings precision. It forecasts demand using sales trends, seasonality, and market shifts. Automation handles reorders, tracking, and reporting, giving teams time to focus on strategy.

Growth demands real-time visibility across all channels—website, marketplace, social. A central system prevents stock errors, improves pricing decisions, and keeps fulfillment seamless.

In a volatile market, smart inventory means smart business. It is the edge that scales.

Step-by-Step Process to Building the AI Inventory Management App

Building AI-driven inventory management software begins with a need and moves through a disciplined path from strategy to scale. Each step shapes the product’s intelligence, usability, and resilience. The outcome is a system that learns, adapts, and grows with the business.

1. Define Objectives and Challenges

Timeline: 1–2 weeks

Every build starts with a problem—stockouts, overstock, misaligned demand. Each drains resources. This phase asks: What pain point matters most? What outcome will move the needle—lower holding costs, better sell-through, fewer stock issues?

Workshops with experts and audits of competitors sharpen the goal. Targets become clear: cut manual tracking by 30%, boost forecast accuracy by 25%, halve deadstock.

Data quality shapes it all. AI thrives on clean, reliable data. This is not a one-time cleanup. It is the start of an ongoing effort. The rule is simple: garbage in, garbage out. Strong data fuels strong AI.

2. Collect and Prepare Data

Timeline: 2–3 weeks

AI performs only as well as the data behind it. Teams gather structured and unstructured inputs—sales history, supplier performance, customer behavior, seasonal trends, market signals.

Cleaning, labeling, and formatting follow. Duplicates are removed. Anomalies are flagged. Missing values are addressed. What remains is usable, trusted data—fuel for learning.

3. Choose the Right AI Model and Design UX/UI

Timeline: 2–4 weeks

With goals defined and data prepared, model selection begins. Forecasting engines need supervised learning. Visual tracking needs computer vision. Anomaly detection benefits from unsupervised techniques.

In parallel, UI/UX takes shape. Wireframes bring structure. Prototypes test logic. The design serves one goal—clarity in decision-making for users across roles, from warehouse operators to procurement heads.

4. Train AI Models and Build Backend Architecture

Timeline: 4–6 weeks

Now the system begins to learn. Historical data feeds the models—adjusting weights, refining logic, and detecting patterns. Training continues until the AI reaches stable, accurate performance.

Simultaneously, the backend takes form. APIs, database structures, server logic—all built to scale. The foundation supports AI-driven features like auto-replenishment, smart alerts, and real-time stock updates.

5. Integrate AI Into the Application

Timeline: 2–3 weeks

AI moves from the lab to the product. Models plug into key modules—forecasting dashboards, replenishment engines, and pricing triggers. Integration spans ERP, CRM, and logistics systems to ensure data moves across the stack.

Security wraps around every API call. Fallback logic handles uncertain cases. Speed becomes critical—forecasts must feel instant.

6. Test and Assure Quality

Timeline: 2–3 weeks

Bugs break trust. Quality assurance ensures every part of the system works as expected before users rely on it. Testing covers all paths—functional, performance, and security. Edge cases are simulated: bulk imports, stockouts, surge orders, sync failures.

The system is stressed before it scales. Every scenario is measured. Every failure is fixed. The goal is operational readiness—on any device, under any load.

7. Deploy and Optimize Continuously

Timeline: Deployment in 1 week | Ongoing optimization: Monthly

The product launches typically into a cloud environment that scales with demand. But the build does not end. Models retrain on new patterns. Usage data informs interface changes. APIs evolve with business needs.

Ongoing monitoring tracks performance, accuracy, and uptime. The system grows smarter with every transaction.

This journey rewards those who plan boldly, build carefully, and improve relentlessly. AI inventory management systems built with this clarity scale faster, perform better, and evolve ahead of demand.

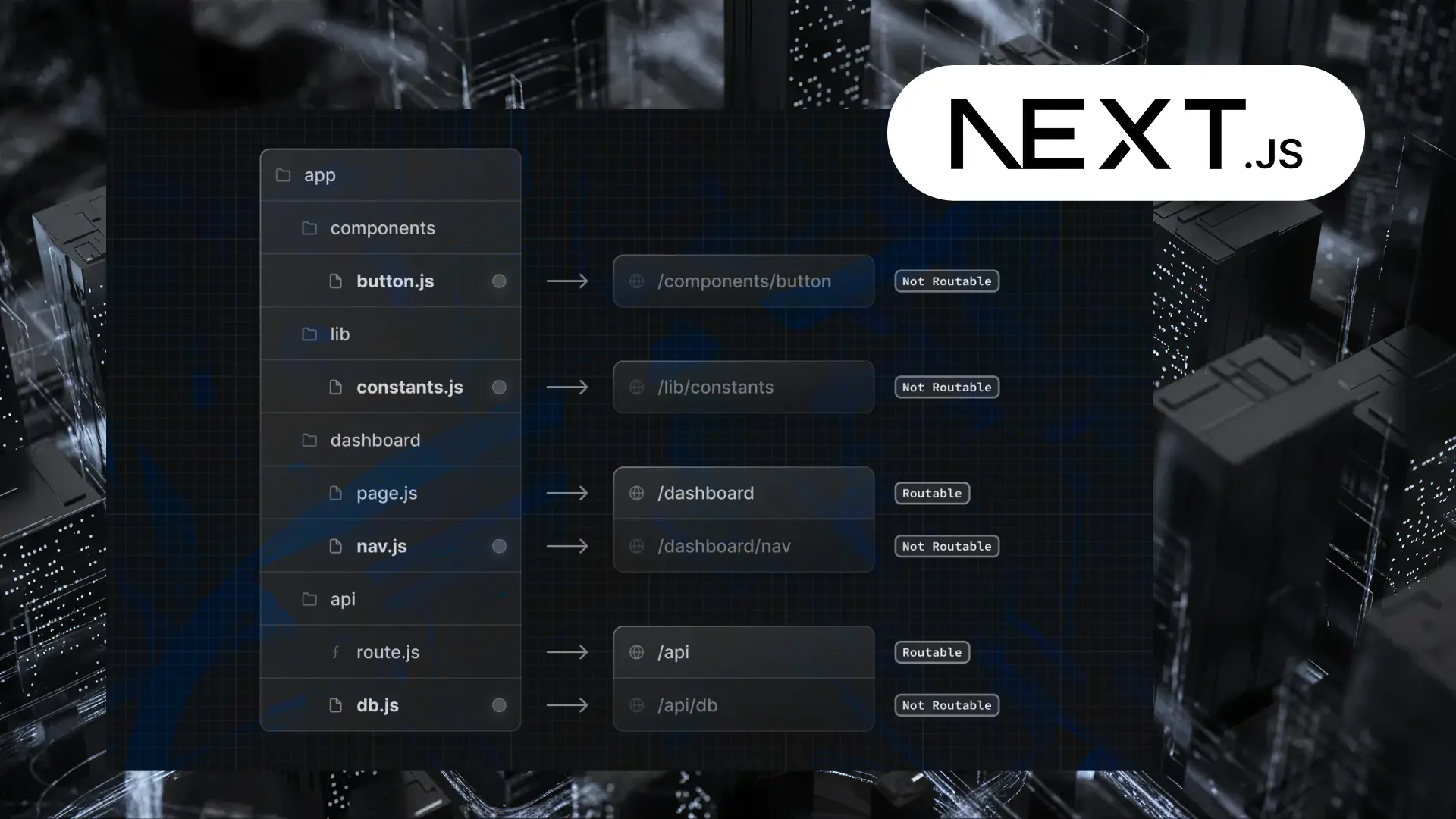

Recommended Tech Stack for AI-Integrated Inventory Management Software

The choice of technology stack significantly impacts the efficiency, scalability, and security of an AI inventory management software.

Layer | Technologies | Purpose |

Front-End Development | HTML5, CSS3, JavaScript, React.js, Angular, Vue.js, Bootstrap, Tailwind CSS | Build dynamic, responsive dashboards and user-friendly inventory interfaces. Ensure cross-device adaptability and seamless UX across e-commerce channels. |

Back-End Development | Node.js, Python (Django, Flask), Java (Spring Boot), C# (.NET Core), Go, Rust | Manage system logic, real-time processing, and integrations. Deliver robust APIs and business rules for AI-driven inventory features. |

API Layer | RESTful APIs, GraphQL | Facilitate efficient communication between front-end, back-end, and third-party platforms. Support real-time inventory sync and AI model deployment. |

Databases | MySQL, PostgreSQL, MongoDB, Microsoft SQL Server, SQLite | Store structured and unstructured inventory data. Enable scalable, secure, and high-performance queries for real-time inventory tracking. |

AI/ML Frameworks | TensorFlow, PyTorch, Scikit-learn, AutoML, MLflow | Train, deploy, and manage AI models for demand forecasting, anomaly detection, and dynamic stock optimization. |

Cloud Infrastructure | AWS, Google Cloud Platform (GCP), Microsoft Azure | Provide scalable compute and storage for AI in inventory management apps. Host models, data pipelines, and serverless backends securely. |

DevOps & Deployment | Docker, Kubernetes, GitHub Actions, Jenkins | Enable continuous deployment and horizontal scaling. Support containerized AI services for real-time inventory decisions. |

Third-Party Integrations | QuickBooks, Xero, ShipStation, EasyPost, Stripe, PayPal, Twilio, SendGrid | Connect inventory workflows with accounting, logistics, payments, and communication platforms. Ensure unified e-commerce operations. |

Mobile Development (Optional) | Flutter, React Native, Kotlin (Android), Swift (iOS) | Extend inventory management features to mobile devices. Enable real-time updates, barcode scans, and on-the-go analytics. |

This technology stack enables businesses to build a scalable, secure, AI-powered inventory management system that supports real-time tracking, predictive insights, and seamless integration across cloud and mobile environments.

Why Build Fully Custom? Off-the-Shelf vs. Custom Inventory Management Software

The first decision shapes everything that follows: build from the ground up or plug into something pre-built. Both paths solve a problem, but only one builds an advantage.

Off-the-Shelf Solutions: Fast Setup, Fixed Structure

Pre-built platforms work out of the box. They ship with standard modules for stock tracking, basic reporting, and multi-channel sync. Most come with subscription tiers, managed support, and vendor-driven updates.

Who They Work For:

Small to mid-sized businesses with predictable workflows and standard operating needs.

Strengths:

- Quick deployment (1–2 weeks)

- Lower upfront cost ($2,000–$15,000 annually)

- Vendor-managed updates and support

Limitations:

- Features fit the average, not the edge cases

- Custom workflows require workarounds or third-party integrations

- Data ownership and platform control sit with the provider

- Subscription fees scale with usage, driving long-term cost

Off-the-shelf solutions solve short-term gaps. It rarely fits evolving businesses with complex operations.

Custom Solutions: Precision at Scale

Custom inventory management software is built for how the business runs, not how vendors think it should run. Every module maps to a real workflow. AI models train on proprietary data. Interfaces match user roles. Systems speak directly to ERPs, WMS, or legacy tools through tailored APIs.

Who It Serves Best:

Multi-warehouse operations, regulated industries, high SKU turnover brands, and businesses integrating with custom commerce stacks.

Strengths:

- Tailored features that match unique processes

- Seamless integration with internal systems

- Scalable architecture that grows with business

- One-time cost structure with controlled TCO over time

- Complete platform ownership and data governance

Limitations:

- Longer go-to-market timeline

- Requires internal or partner support for maintenance

But what custom lacks in speed, it returns in ownership. Businesses define the roadmap, scale without constraints, and cut recurring fees that balloon over time.

Final Word

If the business runs lean, follows standard flows, or seeks speed above control, off-the-shelf works. If the operation spans warehouses, channels, and custom workflows—and seeks differentiation, custom is the strategic bet.

Short-term cost vs. long-term value. The answer depends on what you plan to build beyond the software.

Core Features of an AI Inventory Management App

AI Inventory Management apps help e-commerce businesses predict demand, monitor stock in real time, and automate reordering. This means fewer stockouts, lower storage costs, and faster, more accurate fulfillment at every stage.

1. AI-Powered Demand Forecasting

Analyze real-time sales, seasonality, and external market shifts to predict demand with accuracy and reduce waste.

2. Real-Time Inventory Tracking

Sync stock data across warehouses and sales channels to ensure availability and eliminate manual errors.

3. AI-Based Stock Replenishment

Trigger dynamic reorders based on sales velocity, consumption patterns, and supplier lead times.

4. Smart Supplier Performance Monitoring

Track fill rates, delivery delays, and cost fluctuations. Shift procurement to more reliable vendors automatically.

5. Warehouse Optimization with AI

Automate pick paths, slotting, and labor distribution to speed up fulfillment and lower operating costs.

6. Multi-Channel Inventory Balancing

Reallocate stock across stores, marketplaces, and warehouses based on predicted demand and fulfillment efficiency.

7. Anomaly Detection & Risk Alerts

Detect unusual stock movements, theft patterns, or demand surges before they disrupt supply.

8. RFID & Barcode Integration

Digitize item tracking to reduce manual errors, cut scanning time, and maintain SKU-level visibility.

9. AI-Driven Pricing & Promotions

Adjust pricing in real-time based on stock levels, customer behavior, and market demand.

10. Returns Intelligence

Learn from return trends. Automate restocking, reduce revenue loss, and enhance the post-sale experience.

11. Predictive Maintenance for Equipment

Anticipate wear on warehouse assets using IoT sensor data—preventing downtime before it costs time.

12. AI-Powered Chatbot Support

Enable quick access to live stock, reorder status, and trend insights—conversationally, without reports.

Kunal Kumar

Chief Operating Officer

AI Use Cases in Inventory Management

AI transforms inventory from a static backend function to a dynamic, intelligence-led engine that drives accuracy, adaptability, and scale.

1. Demand Forecasting

Accurate forecasting prevents missed revenue and excess stock. A fast-fashion brand with weekly drops once relied on gut feel and spreadsheets—until AI models began predicting SKU-level demand using past sales, weather, and marketing calendars. Their forecast accuracy rose by 34%, aligning stock to real market intent.

2. Inventory Optimization

AI continuously balances stock across channels, adjusting buffer stock, reorder points, and safety thresholds. In a grocery chain operating across metro and Tier 2 cities, AI helped reduce excess stock of perishable items in low-turnover areas while auto-scaling replenishment in high-velocity zones, cutting wastage by 23%.

3. Real-Time Inventory Tracking with IoT

RFID tags and sensors stream live data across supply chains. For a vaccine logistics company, real-time IoT updates flagged a temperature dip mid-shipment. AI rerouted the container to a climate-stable zone and flagged the compromised lot—preventing distribution of unsafe stock and saving regulatory penalties.

5. Returns Intelligence

High return rates erode margins and customer trust. AI clusters return reasons—wrong size, product mismatch, late delivery—and tracks them by region. A GeekyAnts client in fashion tech used this to reroute SKUs with high return rates to markets with better conversion and fewer mismatches, improving retention.

6. Inventory Reconciliation

AI monitors discrepancies between physical stock and recorded inventory. In a warehouse managing 10,000+ SKUs, shelf-scanning bots flagged mismatched counts in real time. AI cross-referenced logs, corrected quantities, and reallocated restock decisions—removing the need for monthly blind audits.

7. Inventory Analytics

Knowing what’s sitting unsold matters as much as knowing what sells. AI scans turnover rates, warehouse costs, and carrying margins. One retail chain spotted that chargers for an outdated phone model sat idle for 90+ days. AI flagged them for clearance, freeing up shelf space for faster-moving accessories.

8. Material Shortage Prediction

When chip imports slowed from Southeast Asia, an electronics player received AI alerts tied to port logs, freight data, and vendor patterns. It secured alternate sourcing two weeks early. AI turns logistics blind spots into forward-looking plans that keep production on track.

9. Warehouse Automation

AI orchestrates labor and layout. For a B2B distributor handling 20,000 daily orders, the system reconfigured shelf slots based on item frequency, while pick-path logic minimized worker movement. Post-deployment, picking speed improved by 37%, and manual errors dropped.

10. Dynamic Pricing

Stale inventory bleeds cash. A GeekyAnts use case for a mid-size retail partner involved integrating dynamic pricing into their dashboard. When high-value items hit 90+ days in stock, AI automatically adjusted prices based on demand elasticity, helping move excess stock while retaining profitability.

11. Batch & Expiry Tracking

Perishables need priority. A food logistics firm leveraged AI to rotate dairy inventory based on expiry proximity. Orders from partners with high throughput were prioritized for near-expiry items, cutting spoilage by half and ensuring compliance without last-minute markdowns.

12. Risk Assessment & Disruption Planning

AI scores risk across vendors, regions, and supply clusters. During a transport strike, a global wholesaler received a spike alert from the AI system—based on news signals, shipment logs, and regional chatter—days before delays began. The team shifted to alternate trucking partners in advance.

13. Localization Strategy

One size does not fit all regions. AI maps demand density, size curves, and preferences by region. A sportswear brand learned that their northern customers preferred darker tones and larger sizes. AI localized inventory allocation, improving sell-through and reducing inter-warehouse transfers.

14. AI-Powered Inventory Auditing

Drone-based audits powered by computer vision reduce manual errors. A retail chain deployed aerial bots to scan rack SKUs. The AI flagged two categories frequently placed in the wrong bins, cutting misplaced inventory rates by 41% within weeks.

Each of these use cases is a compound gain: faster insight, leaner stock, tighter workflows, fewer surprises. AI in inventory management does not replace teams—it makes them faster, sharper, and future-ready.

Cost Considerations for AI-Integrated Inventory Software

Building AI-powered inventory software is not a one-size decision—it is a layered investment that reflects the depth of your operations, the complexity of your workflows, and the speed at which you plan to scale. Below is a clear breakdown of what that investment looks like and what it buys you.

Basic AI Inventory Software (MVP)

Investment: $10,000 – $40,000

This build includes core features: product listings, manual stock updates, dashboard reporting, and basic AI alerts—like stock threshold notifications or early-stage demand predictions.

Mid-Level AI Inventory Software

Investment: $40,000 – $100,000

At this stage, features expand. The system covers multi-channel sync (web + marketplaces), automated reordering, centralized stock visibility, and smarter analytics. AI supports forecasting, basic automation, and inventory accuracy across multiple zones.

Enterprise-Level AI Inventory Software

Investment: $80,000 – $250,000+

These are high-scale builds. Every module is tightly integrated. AI runs core decision engines—slotting logic, dynamic reorder points, risk scoring, predictive maintenance. APIs connect the system to ERP, CRM, WMS, and third-party logistics.

Highly customized enterprise systems can exceed $300,000–$500,000 when built for high concurrency, AI-first warehousing, and global operations.

Module-Level Cost Breakdown

Module | Estimated Cost |

UI/UX Design | $3,000 – $8,000 |

Product & Inventory Core | $5,000 – $15,000 |

Multi-Channel Integration | $4,000 – $10,000 |

Order Management System | $5,000 – $12,000 |

Warehouse Management Module | $6,000 – $15,000 |

AI Forecasting Engine | $6,000 – $18,000 |

One GeekyAnts client requested only two AI modules—forecasting and reordering—while integrating them with their legacy OMS. By avoiding a full-scale redesign, the company reduced initial spend by 30%, launched within 12 weeks, and met accuracy targets early.

Ongoing Costs & ROI Tracking

Annual Maintenance: $2,000 – $10,000

These costs support cloud scaling, model retraining, API upgrades, and ongoing updates.

Unlocking the Full Potential of AI Inventory Management Software—For E-commerce Businesses

E-commerce moves fast—inventory must move faster. AI brings intelligence to every layer of the inventory lifecycle, connecting forecasts to fulfillment and turning operational noise into actionable insight.

Demand Forecasting with Precision

AI analyzes more than just sales history. It reads patterns across seasonality, promotions, regional trends, competitor pricing, and even weather. This multi-variable modeling allows businesses to predict demand before it hits.

By accurately aligning stock to actual purchase behavior, businesses reduce missed sales and avoid excess inventory. A fashion retailer, for instance, used AI-driven forecasts to optimize regional inventory for a festival sale, cutting stockouts by 42% and boosting sell-through by 38%.

Measurable Cost Reduction

Every unit stored too long drains profit. AI addresses cost at multiple points:

- Carrying cost drops as inventory levels match real-time demand.

- Deadstock and spoilage decline—AI identifies slow movers early, pushing dynamic pricing or reallocation.

- Procurement costs stabilize—AI recommends optimal order quantities and reorder points based on sales velocity and supplier behavior.

- Emergency shipments reduce—With forecasts in place, last-minute logistics shrink.

In one case, a health foods brand used AI to lower perishable waste by 31% by syncing procurement to regional sales trends and shelf life data.

Operational Efficiency Without Complexity

AI reduces friction inside the warehouse and across the backend.

- Automated replenishment eliminates human delay.

- Inventory tracking stays live across all warehouses and channels.

- Slotting, picking, and packing routes adjust based on real-time demand patterns.

- Manual entry drops as systems communicate through clean APIs.

This translates into faster fulfillment cycles and lower labor costs. A multi-warehouse D2C brand saw a 28% reduction in fulfillment time after deploying AI for warehouse pathing and stock positioning.

Real-Time Visibility, Company-Wide

Inventory does not live in spreadsheets anymore. AI-powered dashboards sync stock status from sales channels, suppliers, and logistics in real time. This enables:

- Immediate exception handling

- Coordinated stock transfers

- Informed promotional planning

Teams gain clarity across functions, from procurement to merchandising, without relying on static reports.

Stronger Customer Experience

AI helps businesses promise what they can deliver. When inventory is accurate, delivery estimates become reliable. Personalized offers get smarter as systems link stock availability with user behavior.

Stockouts drop. Cancellations decline. Repeat purchase rates rise. A mid-sized apparel brand tied AI inventory data with its CRM, resulting in a 22% lift in repeat purchases driven by real-time stock-aware recommendations.

Intelligent Decision-Making

AI generates insight. It detects when to reorder, where to shift stock, how to price stale SKUs, and when to scale or pause a promotion.

- Scenario simulation lets businesses model disruptions, price shifts, or demand surges.

- AI weighs variables faster than spreadsheets ever could, enabling quicker, more confident action.

Smarter Supplier Management

Reliability matters. AI tracks vendor performance—on-time delivery, pricing, fill rates—and flags underperformance early.

Procurement teams gain leverage. Risk exposure drops. Delays become manageable instead of chaotic.

Built to Scale

As product lines expand, warehouses multiply, and sales channels diversify, manual inventory workflows break down. AI systems scale automatically, adapting to complexity without adding friction. They learn from new market conditions, product launches, and global shifts, making them more future-proof than static systems.

Businesses maintain speed even as SKUs grow from 500 to 5,000 and fulfillment zones go from one to ten.

Higher Margins, Not Just Lower Costs

AI delivers compounding gains—less waste, more accurate forecasting, better pricing, and tighter operations. These advantages do not simply reduce cost; they elevate margin.

For e-commerce, where volume and velocity define growth, AI inventory systems shift the curve—from reactive to predictive, from fragmented to synchronized.

Challenges of Implementing AI in Inventory Management App & Solution to Overcome

AI-driven inventory management app offers speed, accuracy, and control, but success depends on how it is implemented. Below are the most common challenges businesses face, along with actionable solutions to overcome them.

1. Data Quality and Availability

AI needs clean, structured data to make accurate predictions. Most businesses struggle with fragmented formats, missing values, or insufficient history. Startups face added difficulty with limited past data.

Solution:

Build a strong data foundation early. Standardize formats across systems, validate incoming records, and invest in cleansing tools. Focus on granular item-location-day-level data—this drives accurate forecasting and replenishment logic.

2. Integration with Legacy Systems

Legacy ERP, WMS, or CRM platforms may resist integration with AI systems. Data silos, outdated formats, and rigid architectures slow progress.

Solution:

Use lightweight APIs to layer AI tools on top of existing systems. Extract data externally, process through AI pipelines, and return insights via connectors. This phased approach limits disruption and scales with system maturity.

3. High Upfront Investment and Maintenance Cost

AI platforms require initial investment in tech, infrastructure, and implementation. Ongoing costs include model training, cloud usage, and support.

Solution:

Start lean. Deploy modular AI components—forecasting, reordering, or slotting—on scalable cloud infrastructure. Avoid upfront lock-ins. Scale feature sets as ROI emerges. Many firms recover initial costs within months through reduced inventory holding and faster fulfillment.

4. Talent Shortage and Internal Capability Gaps

AI implementation requires people who understand both machine learning and supply chain logic. Finding and retaining this hybrid talent is hard.

Solution:

Partner with experienced AI firms. While their teams manage core build, they invest in internal training. Upskill supply chain and ops teams on AI fundamentals so adoption spreads across roles. Long-term capability is built through cross-functional collaboration.

5. Cybersecurity and Compliance Risks

AI systems handle sensitive operational and financial data. Without strong security, businesses risk breaches and non-compliance with data privacy regulations.

Solution:

Implement encryption, multi-factor authentication, role-based access control, and audit trails. Conduct regular security reviews. Align with standards like SOC 2, ISO 27001, and GDPR. Strong data practices build trust and resilience.

6. Over-Reliance on Automation

Blind trust in AI creates risk. Models trained on historic data may fail under new conditions or market shocks.

Solution:

Keep humans in the loop, especially in early rollout. Use AI to recommend, not decide. Track model accuracy, allow override logging, and retrain frequently. The best systems combine automation with human judgment.

7. Bias in Data and Models

AI learns from historical data, and that data can carry hidden biases—regional, seasonal, or demographic. Left unchecked, these biases can skew predictions, reinforce inequities, and reduce model accuracy.

Solution:

Regularly audit model outputs for fairness. Use diverse, representative data to train models. Apply explainable AI (XAI) techniques to understand decisions and spot unintended patterns. A fair AI system protects trust and drives better outcomes.

How GeekyAnts Can Help You Build AI-Powered Inventory Management Software

At GeekyAnts, we bring years of cross-industry expertise in AI engineering and full-stack development, with a strong foundation in custom AI models, scalable cloud architecture, and intelligent systems design. From predictive inventory to real-time warehouse optimization, we build AI-powered inventory solutions tailored to scale and perform. We deliver outcomes.

Our Track Record in AI for Operations

We have built production-grade systems that span across logistics, healthcare, retail, and supply chain, including:

- Pharmacy Automation Suite – Developed for predictive inventory control, regulatory compliance, and real-time stock traceability for enterprise-scale pharmacy networks.

- Supply Chain Coordination Tools – AI-enhanced tools that enable intelligent routing, just-in-time stock delivery, and warehouse optimization.

- Generative AI Inventory Bot – Built with LLMs to dynamically answer SKU-level inventory queries for internal supply teams in fast-paced FMCG distribution.

Each system is cloud-native, secure, and designed for continuous learning and adaptability.

AI Expertise That Aligns with Business Goals

Whether it is fine-tuning a predictive model, integrating with IoT sensors, or building autonomous restocking logic, we deliver:

- Bespoke Generative AI Solutions powered by GPT, LLaMA, LangChain, and Transformer-based architecture.

- Forecasting-Driven Interfaces with UX that speaks business KPIs: demand spikes, reorder points, lead time fluctuations.

- Robust API Orchestration for dynamic pricing, inventory balancing, and vendor negotiation logic.

From AI-first startups to enterprise-grade inventory modernization, we accelerate your roadmap with precision and scale.

The bottom line

Traditional inventory systems crack under the pressure of today’s e-commerce demands—fragmented sales channels, unpredictable demand, and complex logistics. Manual checks and static rules delay reorders, inflate costs, and frustrate customers.

AI flips this bottleneck into a growth engine.

Smart algorithms forecast demand at the SKU level, adapting to seasonality, trends, and real-time signals. Integrated with IoT and robotics, AI enables livestock visibility, automated replenishment, and dynamic distribution across channels.

In North America, nearly 50% of logistics runs on AI, for good reason. AI reduces stockouts, slashes lead times, and improves margins without bloating costs.

In a space where milliseconds matter, AI is the edge. The winners will be those who move from reactive inventory to predictive intelligence.

FAQs

1. How Does AI Improve Inventory Management in E-commerce and Retail?

AI enhances inventory management by using predictive analytics, machine learning, and real-time data synchronization to automate stock decisions. It minimizes overstock and stockouts, optimizes warehouse space, and enables faster fulfillment. AI-powered systems also improve demand forecasting, automate reordering, and reduce manual intervention, leading to fewer errors, better cash flow, and improved customer satisfaction.

2. How Long Does It Take to Build an AI-Based Inventory Management System?

Building a custom AI inventory management system takes 4 to 8 months, depending on complexity, integrations, and AI scope. A basic system with stock tracking and automated reordering can be built in 4 months, while full-suite solutions with demand forecasting, supplier analytics, and real-time warehouse intelligence may take up to 8 months or more. Leveraging APIs and pre-built AI models can shorten the timeline.

3. What Is the Impact of Artificial Intelligence on Inventory Management?

AI transforms inventory management from reactive to predictive. It helps businesses forecast demand more accurately, manage supply chain volatility, automate warehouse operations, and reduce carrying costs. AI identifies patterns in customer behavior, seasonality, and logistics constraints, allowing businesses to make smarter, data-driven stocking decisions and reduce operational inefficiencies.

4. What Types of Businesses Can Benefit from AI Inventory Management Solutions?

AI inventory management is ideal for:

- E-commerce and D2C Brands: Real-time stock syncing and dynamic demand prediction.

- Retail Chains: Store-level optimization, shrinkage reduction, and multi-location management.

- Manufacturers: Forecasting raw material needs and reducing downtime.

- Pharmaceuticals & FMCG: Managing expiry-sensitive and fast-moving goods.

- Logistics & Warehousing Providers: Route and storage optimization using AI.

Virtually any business managing high-volume SKUs or fast inventory turnover benefits from AI integration.

5. How Much Does It Cost to Build an AI-Powered Inventory Management System in the US?

Costs vary based on features, scalability, and industry compliance. A basic AI-enabled inventory tracking system costs $40,000–$60,000. This MVP approach suits smaller e-commerce businesses or those new to AI, helping them gain insights and build confidence before scaling. Enterprise-grade platforms with full-suite automation, IoT integration, and predictive analytics can cost $100,000–$250,000+. Pricing also depends on custom AI model training, third-party API usage, and regulatory considerations in industries like pharma or food.

Related Articles

Dive deep into our research and insights. In our articles and blogs, we explore topics on design, how it relates to development, and impact of various trends to businesses.